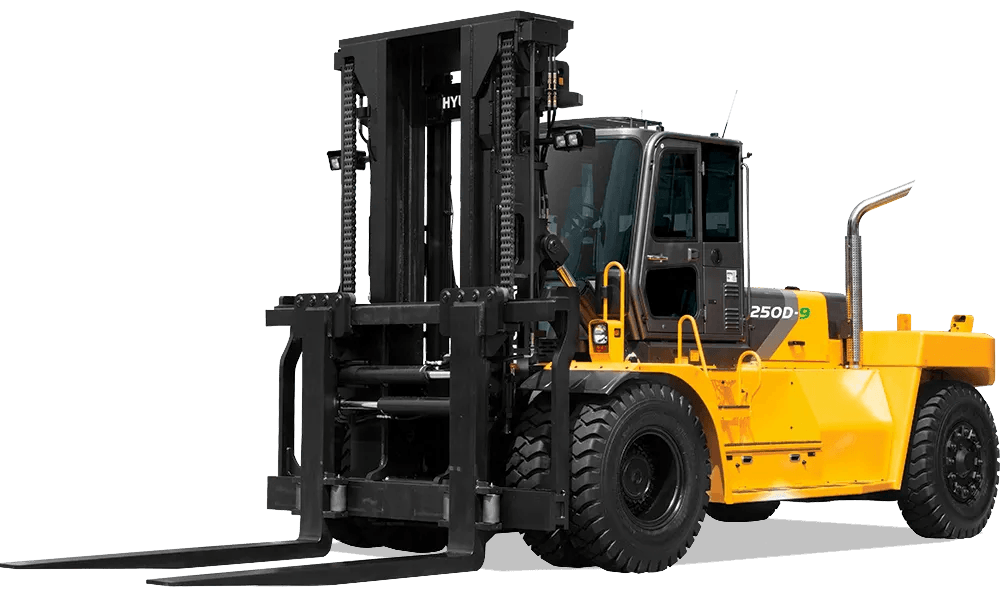

Forklift Dealer Sales, Rentals, Parts & Service In Tampa

Florida's Forklift Dealer Serving Tampa Since 1981.

Forklift Sales, Rentals & Repairs In Florida - Read's Forklift is your one-stop shop for all of your forklift needs. We specialize in new and used lift trucks with a variety on options to choose from! Our knowledgeable staff will work closely together find the right fit that works best just what you need it too be!

➤ 3,000 lbs to 90,000 lbs

(Common Capacities: 5,000 lbs, 6,000 lbs, 8,000 lbs, and 15,000 lbs)

➤ Solid Pnuematic, Cushion, or Rough Terrain

➤Electric, Diesel, LPG/Propane, or Manual

➤ Competitive Market Rate Pricing

➤ Hyundai, Noblelift, SANY, and Lift King

(Some Locations Have Limited Availablity)

➤ 3,000 lbs to 90,000 lbs

(Common Capacities: 5,000 lbs, 6,000 lbs, 8,000 lbs, and 15,000 lbs)

➤ Solid Pnuematic, Cushion, or Rough Terrain

➤ Electric, Diesel, LPG/Propane, or Manual

➤ Competitive Market Rate Pricing

➤ Taylor, Clark, Hyundai, Toyota, Raymond, Doosan, Wiggins, Hyster-Yale, Hiab Moffett, Komatsu, Crown, Heli, Linde, Caterpillar, Volvo, Hangcha, Hoist, Kalmar, Mitsubishi, Nissian, Unicarriers, Princeton Piggy-Back(PB+), Navigator, and More!

Forklifts & Equipment For Rent

➤ 3,000 lbs to 55,000 lbs

➤ Solid Pnuematic, Cushion, or Rough Terrain

➤ Electric, Diesel, LPG/Propane, or Manual

➤ Available Daily, Weekly, or Monthly

(Conditions May Apply)

➤ Competitive Market Rate Pricing

➤ OTTAWA, YARD DOG, SPOTTER TRUCK

(Off-Road/DOT Available)

-

Rental Forklift Hyundai 25L-7A In Orlando

5,000lbsButton -

Rental Forklift Hyundai 20BT-9U In Orlando

3,500lbsButton -

Rental Forklift Hyundai 160D-9 In Orlando

35,000lbsButton -

Rental Forklift Toyota 8FGCU35-BCS In Orlando

8,000Button -

Rental Forklift Hyundai 70D-9 In Florida

15,500lbsButton -

Rental Forklift Taylor X360M In Florida

36,000lbsButton -

Rental Forklift Taylor THD160 In Florida

16,000lbsButton -

Rental Forklift Taylor TE520M In Florida

52,000lbsButton -

Rental Forklift Taylor TE160S In Florida

16,000lbsButton -

Rental TrailerSpotter Ottawa 4×2 DOT/EPA Terminal Tractor In Florida

0Button -

Rental TrailerSpotter Ottawa 4×2 OFF-ROAD Terminal Tractor In Florida

0Button -

Rental TrailerSpotter Ottawa 4×2 T2 Terminal Tractor In Florida

0Button -

Rental TrailerSpotter Ottawa 6×4 DOT/EPA Terminal Tractor In Florida

0Button -

Rental TrailerSpotter Ottawa 4x4 TR618i Terminal Tractor In Florida

0Button

Allied Equipment Sales & Rentals

➤ Light Towers

➤ Scissor Lift

➤ Telehandlers

➤ Aerial Lifts

➤ Boom Lifts

➤ Generators

(Conditions May Apply)

-

A

Air Filters

Alternators

Axles

-

B

Backup Alarms

Batteries

Battery Terminals

Ball Bearings

Bell Cranks

Brake Cylinders

Brake Drums

Brake Lights

Brake Pads

Breather Caps

Brushes

Brushings

-

C

Carburetors

Cards

Chargers

Connectors

Contractors

Controllers

-

D

Distributor Caps

Drive Axles

Drive Motors

-

E

Engine Blocks

Engine Heads

Engines Complete

-

F

Fan Belts

Fan Blades

Fork Pin Kits

Fork Accessories

Forks ITA

Fuel Filters

Fuel Pumps

Fuses

-

G

Gaskets

Gauges

Gears

-

H

Headlights

Heaters

Horns

Hour Meters

Hydraulic Control Valves

Hydraulic Cylinders

Hydraulic Filters

Hydraulic Hoses

Hydraulic Oil

Hydraulic Pump Motors

Hydraulic Pumps

-

I

Inching Cylinders

Injection Pumps

-

K

Keys

King Pins

Knuckles

-

L

Load Wheels

Lights

LPG Tanks

-

M

Manifolds

Mast Chain

Mast Rollers

Master Cylinders

Mirrors

Mufflers

-

O

Oil

Oil Filters

Overhead Guards

-

P

Pedals

Propane Brackets

Propane Mixers

Propane Regulators

Propane Tanks

-

R

Radiator Hoses

Radiators

Relays

Rims

Ring Gears

Rollers

-

S

Safety Items

Seal Beams

Seals

Seat Belts

Seats

Shims

Slave Cylinders

Solenoids

Spark Plug Wire Sets

Spark Plugs

Starters OEM

Steer Axles

Steering Cylinders

Steering Spinner Knobs

Steering Wheels

Strobe Lights

Switches

-

T

Tails Lights

Tank Brackets

Thermostats

Tie Rod Ends

Tilt Cylinders

Tilt Cylinder Pins

TIres (Cushion/Pneumatic)

Torque Converters

Transaxles

Transmissions

-

W

Water Pumps

Wheels

Wiper Motors

Wiring Harnesses

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Explore

Testimonials

“Reads hands down always has my best interest in mind. ......That means a lot to me and that's why I'll always go back!”

Live Oak Pallets, LLC

“Would highly recommend their service to anyone who needs forklift help.”

Ethan Nelson

“I appreciate the work you guys did. Will call again!”

Audio & Visual Expo Orlando, LLC

Solutions For Every Industry

Contact Us

We will get back to you as soon as possible

Please try again later

ABOUT

Read's Forklift, Inc has been in business for over 40 years and is headquartered in Live Oak, Florida.